24.5%! The world record efficiency of all perovskite laminated components was set again in China

2024-02-27 11:31After testing by an international third-party authoritative certification body, its steady state photoelectric conversion efficiency is as high as 24.5%, refreshing the world record efficiency of all-perovskite stack components. It lays the technical foundation for the mass production and commercial application of all perovskite laminated cells. The relevant research results were presented on February 23, 2024 under the title "Homogeneous crystallization and buried interface passivation for perovskite tandem solar modules". Published in the journal Science.

In order to achieve the major strategic goal of "double carbon" and accelerate the construction of a new low-carbon clean energy system, the National Energy Board and the Ministry of Science and Technology jointly issued the "14th Five-Year Plan for scientific and technological Innovation in the energy Field" clearly pointed out that it is necessary to vigorously carry out research on the preparation and industrialization of high-efficiency laminated battery perovskite/perovskite (referred to as "all perovskite"). Professor Tan Hairen's research group has been committed to the research of new all-perovskite laminated battery technology. In recent years, the team has achieved a small-area all-perovskite laminated battery with a certified record efficiency of 28.0% through the grain surface interface passivation strategy (Nature 620, 994, 2023). A large area laminated component with a certified efficiency of 21.7% was further achieved through mass producible preparation technology (Science 376, 762, 2022). However, the photoelectric conversion efficiency of large-area all-perovskite laminated modules has a big gap with that of small-area laminated cells, which restricts the industrialization process of perovskite laminated cells. The uniform preparation of narrow band gap perovskite films is a key problem to limit the performance improvement of large-area components. The existing large-scale preparation technology development focuses on conventional bandgap perovskite films, but tin perovskite films have fast crystallization speed, short time window for large-scale production and preparation, and are prone to the problem of uneven film formation. In addition, when the narrow band gap perovskite is prepared by scraping, the air blowing assisted process causes slow up-down crystallization. This asynchronous crystallization process causes a large number of defects at the bottom interface of the lead-tin perovskite, which seriously limits the photoelectric performance of the battery.

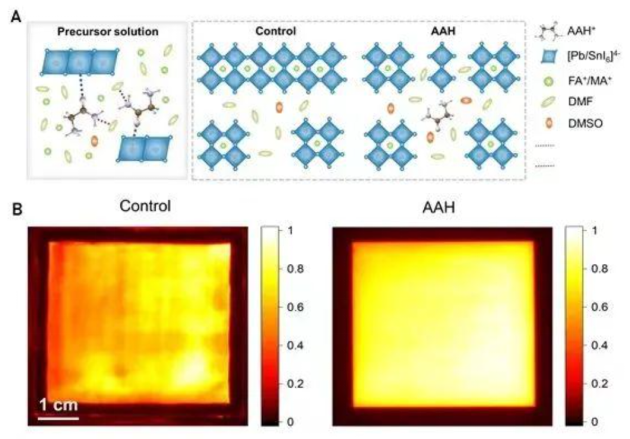

In order to solve the above key problems, Professor Tan Hairen's research team achieved the crystallization regulation and buried interface passivation of lead-tin perovskite by adding a multifunctional zwitterionic buffer - glycoamine hydrochloride to the precursor solution. Glycine hydrochloride can form hydrogen bonds with organic cations and solvents of perovskite, and form complexes with metal halides in

perovskite precursors, inhibit solvent volatilization during the crystallization of perovskite, delay the crystallization rate of perovskite, and significantly extend the preparation window time of large-scale film formation of perovskite films. The large-area, homogeneous preparation of lead-tin perovskite films was realized.